History of the microphone

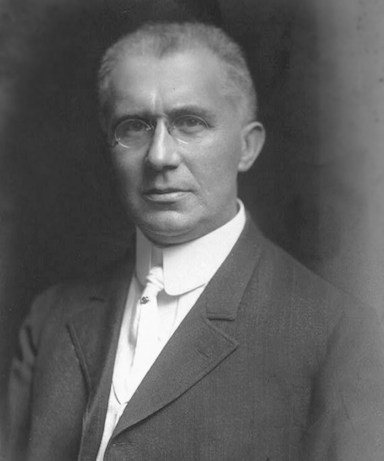

Emile Berliner

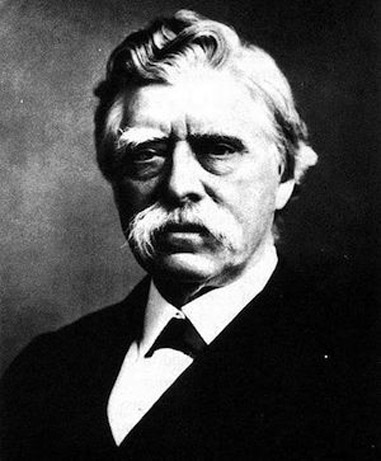

David Edward Hughes

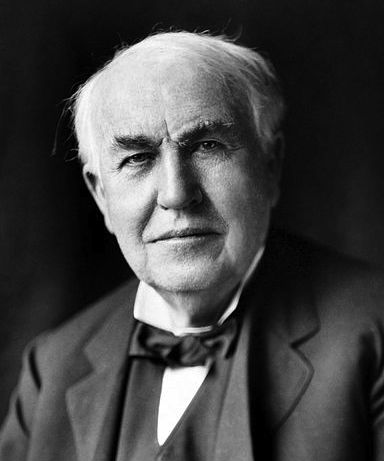

Thomas Edison

Microphone technology and applications have come a long way since those early inventions.

Here’s a quick summary of where it all began to where we’re at now:

- 1665: English physicist, Robert Hooke, developed the cup-and-string phone

- 1876: US inventor, Alexander Graham Bell, invented the liquid microphone

- 1886: US inventor Thomas Alva Edison invented the first carbon microphone

- 1916: WECo researcher, Edward C. Wente developed the condenser microphone

- 1924: German physicist Schottky and Dr. Gerlach co-invented the ribbon microphone

- 1939: User-friendly commercial dynamic mics became widespread

- Present day: Microphone technology continues to develop

The history of the microphone is a fascinating journey that spans several centuries. The microphone, an essential device for converting sound into electrical signals, has played a crucial role in communication, entertainment, and technology. Here’s a brief overview of its development:

Acoustic Devices (19th Century):

- Before the invention of electronic microphones, early attempts to amplify sound involved purely mechanical devices. One example is the “megaphone,” a cone-shaped device used to direct and amplify the human voice.

Carbon Microphone (1870s):

- The first significant breakthrough in microphone technology came with the invention of the carbon microphone by Émile Berliner. This microphone used carbon granules that varied in resistance when subjected to sound waves. As the sound waves compressed and decompressed the carbon, the electrical resistance changed, allowing for the conversion of sound into electrical signals.

Dynamic Microphone (1920s):

- The dynamic microphone was introduced by Western Electric in the early 20th century. It relies on electromagnetic induction to convert sound waves into electrical signals. The diaphragm of the microphone is attached to a coil of wire placed within the magnetic field of a magnet. When sound waves hit the diaphragm, it moves, causing the coil to move within the magnetic field and generate an electrical current.

Condenser Microphone (1916):

- Developed by E.C. Wente at Bell Labs, the condenser microphone uses a diaphragm placed close to a backplate. The space between them serves as a capacitor, and when sound waves hit the diaphragm, the distance between the diaphragm and backplate changes, creating variations in capacitance. This design allows for a more sensitive and accurate reproduction of sound.

Ribbon Microphone (1920s):

- The ribbon microphone was introduced, utilizing a thin strip of metal (typically aluminum) as the diaphragm suspended within a magnetic field. When sound waves hit the ribbon, it vibrates within the magnetic field, generating an electrical current. Ribbon microphones are known for their warm and smooth sound characteristics.

Electret Microphone (1962):

- James West and Gerhard Sessler developed the electret microphone at Bell Labs. This type of microphone uses a permanently charged material (electret) as part of the diaphragm or a backplate. Electret microphones are compact, reliable, and widely used in various applications.

Advancements and Miniaturization (Late 20th Century – Present):

- Over the years, advancements in technology have led to the development of different microphone types, including shotgun microphones, lavalier microphones, and boundary microphones. Miniaturization and improvements in materials and manufacturing processes have also contributed to the widespread use of microphones in diverse fields such as telecommunications, recording studios, broadcasting, and consumer electronics.

The microphone has evolved significantly since its early days, becoming an integral part of our daily lives and revolutionizing how we communicate and record sound.

Who is the real inventor of the microphone ?

The invention of the microphone is attributed to several individuals who made significant contributions over time. Émile Berliner, mentioned earlier, was one of the inventors who played a role in the development of the carbon microphone. Another key figure is David Edward Hughes, who independently invented a carbon microphone around the same time as Berliner.

It’s important to note that the concept of converting sound into electrical signals predates the carbon microphone. Thomas Edison, for instance, worked on various sound-related inventions, including the carbon transmitter used in early telephones. Additionally, Alexander Graham Bell, known for inventing the telephone, also made contributions to microphone technology.

In summary, the development of the microphone involved the collective efforts of multiple inventors over several decades. Different types of microphones, such as carbon, dynamic, condenser, and ribbon, have been invented and improved upon by various individuals. Therefore, attributing the invention of the microphone to a single person is challenging, as it is the result of incremental advancements and collaborative contributions in the field of audio technology.

How did they made the microphones ?

The production of vintage microphones involved a combination of skilled craftsmanship and engineering. The manufacturing processes varied among different companies and eras, but here is a general overview of how vintage microphones were typically made:

- Design and Engineering:

- Microphone production began with the design phase. Engineers and designers conceptualized the microphone’s structure, including the diaphragm, magnet, and housing. They considered the intended use of the microphone and the desired sound characteristics.

- Materials Selection:

- High-quality materials were crucial for building durable and effective microphones. The choice of materials for the diaphragm, magnet, housing, and other components depended on the microphone’s design and intended application.

- Diaphragm Fabrication:

- The diaphragm, a thin, flexible material that vibrates in response to sound waves, was typically made of materials like Mylar, aluminum, or other lightweight alloys. The diaphragm was carefully manufactured to precise specifications.

- Transducer Assembly:

- The transducer is the core element that converts acoustic vibrations into electrical signals. It usually consists of the diaphragm, a backplate, and a magnet. These components were assembled with precision to ensure proper functioning.

- Magnet and Coil Assembly:

- Many vintage microphones used electromagnetic principles for transduction. The magnet and coil assembly were crucial components. The magnet provided a magnetic field, and the coil, attached to the diaphragm, generated an electrical signal when it moved within that field.

- Housing Construction:

- The microphone’s housing or body was crafted from metal, plastic, or a combination of materials. The housing protected the internal components and influenced the microphone’s aesthetics. Some vintage microphones featured intricate and visually appealing designs.

- Wiring and Circuitry:

- Wiring connected the various components of the microphone, creating an electrical circuit. The circuitry played a crucial role in shaping the microphone’s frequency response and overall performance.

- Quality Control:

- Rigorous quality control measures were implemented to ensure that each microphone met the manufacturer’s specifications. This involved testing the microphones for consistency, accuracy, and reliability.

- Assembly and Finishing:

- Skilled technicians assembled the various components of the microphone, securing them within the housing. The finishing touches, such as branding, labeling, and surface treatments, were applied to complete the manufacturing process.

- Testing and Calibration:

- Each microphone underwent testing to ensure it met the specified technical standards. Calibration and adjustments were made to fine-tune the microphone’s performance.

- Packaging and Distribution:

- Once a microphone passed quality control and testing, it was packaged and prepared for distribution. Vintage microphones were then shipped to retailers or directly to end-users.

It’s important to note that advancements in technology, manufacturing techniques, and materials have evolved over the years. The processes described here provide a general overview of how vintage microphones were traditionally made, and modern microphones may involve different methods and materials.